Vacuum Brakes

The Automatic Feed Valve

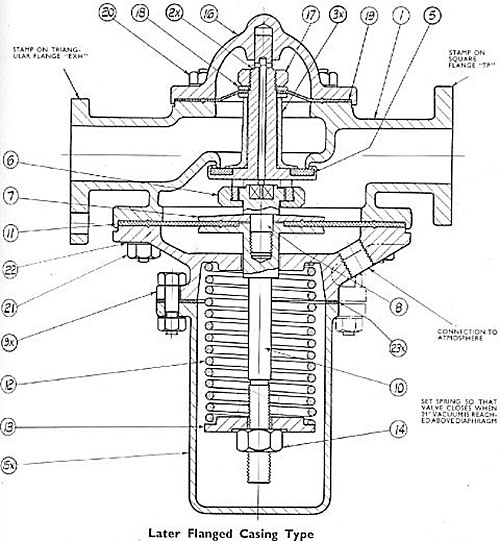

There is one feed valve for each drivers brake valve fitted between the brake valve and the release pipe. It regulates the train pipe vacuum to 21 inches and maintains this so long as the release pipe vacuum is above 21 inches.

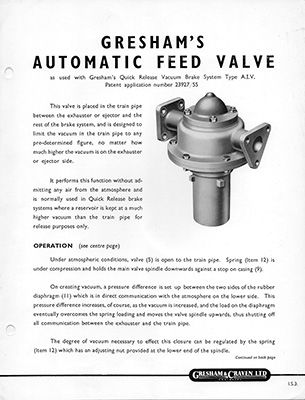

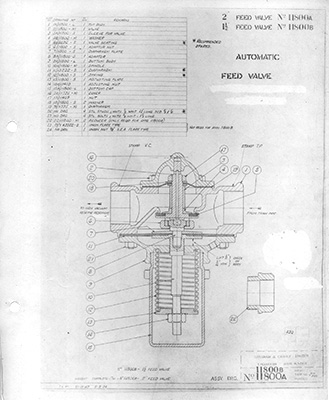

- 1 Top Body

- 2X Valve

- 3X Sleeve for Valve

- 5 Valve Seating

- 6 Adaptor Nut

- 7 Diaphragm Plate

- 8 Adaptor

- 9X Bottom Body

- 10 Spindle

- 11 Diaphragm

- 12 Spring

- 13 Adjusting Plate

- 14 Adjusting Nut

- 15X Bottom Plate

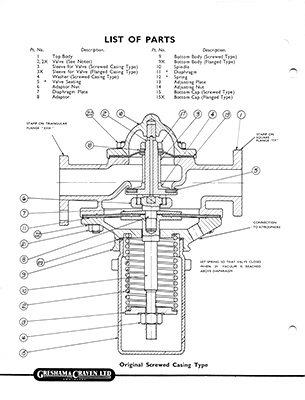

- 16 Cover

- 17 Lock Nut

- 18 Washer

- 19 Diaphragm

- 20 Studs and Nuts, 3/8" BSW

- 21 Bolts and Nuts, 3/8" BSW

- 22 Shakeproof Locking Washers, 3/8" i/d

- 23X Joint

Initially the valve is held off its seat by spring tension and vacuum is allowed to build up in the train pipe. When the vacuum above the main diaphragm is 21 inches atmospheric pressure overcomes spring tension and seats the diaphragm, so opening the valve, air is now extracted by the exhausters and the valve closes again at 21 inches.

The smaller diaphragm is to balance the pressure under the valve.

When changing ends a difference in the train pipe vacuum may be noticed, this means that one of the adjustable feed valves needs resetting.

Details on overhauling feed valves

Gresham & Craven

The valves were supplied by Gresham & Craven who supplied most of the vacuum brake equipment. This is their brochure for the Valve:

And some other G&C literature:

Vacuum Brakes

General Description

Operation

Exhauster

Feed Valve

Isolating Valve

Brake Cylinder

Direct Admission Valve

Driver's Brake Valve

Maintenance:

Adjusting Brakework

Feed Valve Overhaul

Isolating Valve Overhaul