Wickham Railbus

Interior Description

Accommodation

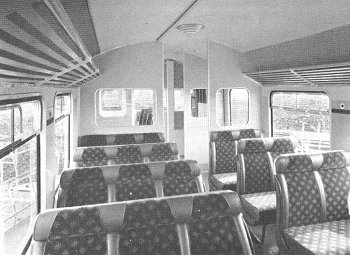

There were two passenger compartments, with space for luggage at the centre. Tubular bus type seats accommodated 44 passengers and there were two drop-down seats for two on each end panel of the car, giving a total capacity of 48. The seats all faced the nearest cab, in an 2 + 3 formation (doubles on the left when facing the driver). The seats, supplied by Pel Ltd., were comfortably upholstered in green patterned moquette with Vynide facings covering moulded Dunlopillo seat squabs and backrests. Over the seats longitudinal Deans' luggage racks accommodated light luggage. These were at an angle giving good headroom but restricted their capacity. Adjacent to the luggage space on either side of the centre doors were housed the standard BR emergency kit and fire extinguisher.

There were four fixed Beclawat side windows in each passenger compartment. Along with the two large front windows and the light oak grained finished Warerite panels (supplied by Bakelight Ltd) on aluminium paneling imparted a bright and spacious appearance to the interior. The fixed side windows were fitted with glazed sliding top panels, and with the full drop windows at each corner of the car and seven roof ventilators, there was plenty of ventilation. For heating in cold weather there was one independent oil-fired Smiths' heater, which could also circulate fresh unheated air in hot weather. It distributed air through ducts in the floor and discharged into the saloon through shallow circular domes under seats.

The full-height vestibule partitions were fitted with large windows to provide through visibility.

Polished aluminium chequer plate was used to line the vestibule and house the sliding doors, otherwise a marble green neoprene rubber floor covering was fitted.

Retractable steps with inside operating gear were fitted.

In addition to the normal row of 60W lights, a light positioned inside each doorway switched on when the door was opened. Saloon lighting equipment was supplied by J Stone & Co (Deptford) Ltd.

Cabs

The fully enclosed driver's compartments on the left hand side at each was comfortably equipped with Chapman upholstered seats with quick adjustment for height and leg room, and the control desks were arranged conveniently to the front. The throttle control on the left was similar in action to normal, comprising a tram-type control handle with deadman's device, but action was purely mechanical.

Gear change, on the right was of the miniature gate type identical to those fitted to the London Transport of the time buses but interlocked with the forward and reverse control so that the change was only operative when forward or reverse gear was engaged. Also on the right was the operating valve for the Clayton-Dewandre compressed air brake operating clasp type shoes on each wheel, a handbrake also being provided for emergency or parking use. Between these controls located on a hinged sloping panel were the speedometer (largest, in the centre), air gauges for air reservoir (left) and brake cylinder (right) pressures and warning lights for correct engine oil pressure and cooling water temperature. These two lights were dim when functioning was correct and glow brightly should oil pressure fail or engines overheat. No indicator was fitted for the forward and reverse gear, for as the vehicle was a single unit correct operation or otherwise was immediately apparent. Instruments were indirectly lighted. Either side of the speedometer were the door control buttons. On a panel mounted vertically to the left of the driver were mounted the main control switch, interior, marker and head light switches, engine start and stop buttons and an ammeter.

The aim was to keep the control gear as simple as possible, (it was pointed out at the time though that it still fell short of the simplicity achieved in the London Transport bus which had a speedometer - for legal reasons - and nothing else except the essential throttle, gear change and brake). Two-note Desilux air-operated horns were fitted to each end of the car with the control valve mounted on the driver's desk.

An air operated windscreen wiper supplied by Trico-Forbeth Ltd. was fitted to the driver's front window, as well as interior sun visor and demister. The driver also had a control for his cab heating; rear and side windows and also door windows were fitted with blinds for night driving and the door was lockable to prevent unauthorised interference with controls. There were three marker lights at each end, the fourth (lower centre) was fitted with a CAV headlamp for illuminating the track.

There was a CAV type A6.8 alternator fitted, belt driven from the auxiliary drive gearbox at 2.8 times engine speed. A germanium rectifier was used. The Nife 170 amp/hr battery of type LR17 were mounted on each side of the underframe near the driving axle.

The horns were supplied by CV Desiderio Ltd.

Summary

Description

Interiors

Suspension

Numbering

Operations

Elliot Track Recorder

Images

Details about the preserved Elliot Wickham railbus can be found here.