Blue Pullman

Interior

Passenger access to the vehicles was through inward opening doors into the entrance vestibules at the ends of the cars which were wide and spacious. At starting and stopping points it was the responsibility of the Pullman Car Attendants to see that before departure all outside passenger doors were properly closed and secured by means of a safety catch fitted to the inside of each door.

The gangways between the cars were also wider than normal width. They were mounted on pivots at the ends of each vehicle. When joined together these semi-floating units between pairs of cars formed a level platform free from the normal gangway oscillation. Rubber seals covered the outside of the gangways and prevented draughts and loss of conditioned air.

The complete train was fully air-conditioned with automatic control of air temperature and humidity. The inward flow of air to the saloons from the air-conditioning plant was through outlets in a duct concealed by the central lighting panel. Particular care was taken to achieve a high standard of sound insulation, and track noise was reduced to a low level. The insulated floors were fully suspended.

The windows at each table were double glazed to prevent condensation and heat

losses, and to provide sound insulation. Clips were provided on the lower

framework between the inner and outer windows to hold a capsule containing

silica-gel crystals. The capsules were fitted at certain periods of the year to

avoid misting of the windows. Should a window become badly misted it was possible for the staff

to clear it by:

a) Removing the table lamp

b) Unscrewing the special screws securing the inner glass

c) Opening the inner glass, the frame of which was hinged at the bottom

d) Cleaning the inner surface of the glass

e) Closing and lock the inner window and replacing the table lamp.

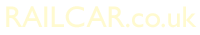

The next image shows the first class seating.

Small venetian blinds were fitted between the two sheets of glass and these blinds could be raised or lowered and the angle of the slats adjusted by means of small control handles fitted at both sides of the windows in the first class or above the windows in the second class saloons. In the first class separate blinds were provided for each half of the passenger windows so that passengers on both sides could adjust individually their own blinds; in the second class only one blind was provided for the whole width of the window.

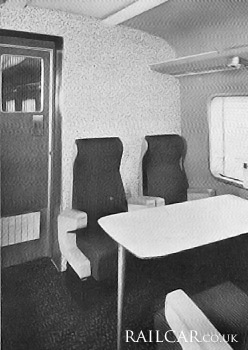

In each car the seating was arranged in facing pairs on one side of the passenger gangway and in facing individual seats on the other, with double or single fixed tables respectively set between them. All seating was of the armchair type with deep foam-rubber cushions upholstered in red or blue striped fabric trimmed with back and grey plastic hide.

The first class seats could be adjusted from the reclining to the upright position, using a control which was fitted in the end of one of the arms and was operated by pressing upward with the fingers, enabling the passenger to adjust the angle of the seat back. The seats were mounted on runners for sliding back and forward to the table. This was operated by a release lever on the framework of the seat, requiring the passenger to reach down and pull up the lever and sliding the seat. Both of these controls were placed on the gangway side of each first class seat.

In the second-class saloons the seats were of the same armchair type but were not adjustable.

All seats on the train were reservable in advance and this facility was given at starting points and all intermediate calling points. For this each seat was numbered individually and the numbers were displayed on the gangway side of the head rest.

The coach registration letters were displayed on metal plates which were inserted in slots provided on the outside of the coaches near the passenger access doors, and on the inside in the end vestibules of each coach.

The lettered plates were reversible, so that when the train is reversed, or one half-set in the train is replaced by another half-set under the maintenance programme or for any other purpose, the correct registration could be displayed. The standard arrangement for WR sets was for the leading vehicle to be 'A' and the rear vehicle 'H'. So the reversible plates were lettered as: Motor cars A/H, Parlour cars (second class) B/G, Kitchen cars C/F and Parlour cars (first class) D/E.

The Pullman Car Company's staff were responsible for the reversing of the car registration plates at the terminal stations.

The interior decor, which varied from vehicle to vehicle, was chosen to give pleasing and colourful combinations, mainly of decorative rosewood and ebony veneers, grey plastic hide, plastic facings, and contrasting seat upholstery. The partitions forming the ends of each passenger saloon were decorated with wood veneers and abstract plastic inlays. Each partition had glazed panels in the access door, the glass having a vertical stripped pattern which acted as a mirror but allowed impeded vision at close quarters.

A press button was provided at each table below the window so that the attendant may be called. When this button was pressed a small green lamp above the table was illuminated to indicate to the attendant where they were required.

A buzzer sounded in the corridor outside the pantry in the kitchen cars and a green lamp above an arrow indicated the direction in which the attendant should proceed.

The call button was cancelled by the Attendant pressing a button placed under the outer edge of the table on the supporting leg and by pressing a further button adjacent to the directional lamps in the corridor of the kitchen cars.

The system was arranged so that each kitchen car served the half of the train of which it formed a part.

The bodyside walls were faced with a plastic hide from floor level up to the continuous hand-luggage racks running along the length of each passenger saloon. Along the racks, walls and ceiling surfaces were lined with plastic in pearl-grey, with a fine black-line pattern superimposed which continued up to the central lighting panel in the ceiling.

The image shows a first class saloon.

The exposed parts of the hand-luggage racks, the table edges, and the window surrounds were all of anodised aluminium, satin finished in aluminium for the first class and in pale gold for the second class. The solid racks had slatted grilles so that any articles placed on the racks may be seen from below. Tiered luggage racks were provided in the end vestibules opposite the toilets and a draught screen of specially toughened glass was fitted adjacent to the vehicle entry door.

The heater grilles, mounted low on the bodyside alongside the seats, were of satin-finished stainless steel.

Floor carpets, in kingfisher blue or cardinal red, were fitted on plastic underlays. The walls of the entrance vestibules at the car ends were faced in pearl-grey plastic, with plastic hide trimming around the inter-car gangway entrances. Coir mat floor covering is used in the vestibules.

In each saloon the main lighting was by twin-white fluorescent tubes in the centre of the ceiling, supplemented by tungsten lamps fitted in the luggage racks above each table. The fluorescent tubes were placed end-to-end and covered by flush-jointed diffusion panels. When illuminated the panels showed as a continuous panel of light running the length of the saloon. Individual table lamps with glass shades were mounted on swan-necked pillars fixed to the bodysides just below window level. Battery operated emergency lighting was also installed.

The equipment of the well-appointed toilets included towel dispensers and hygienic spray washing facilities which gave an automatically timed flow of water, of which the temperature could be regulated as required. The walls were plastic faced in flame, clover-pink, and grey, and the ceilings painted matt-white. Coloured mosaic paving was used for the flooring. Metal fittings were finished in satin chromium plate, with the exception of the skirting beadings of satin-finished anodised aluminium and the satin-finished stainless-steel heater ventilation grills. Separate toilets were provided for the ladies.

Summary

Development

Press run 24/6/60

Press run 7/9/60

Staff difficulties

Ownership agreement

Manufacturer's Publicity

Description

Type 1 - LMR motor car

Type 2 - WR motor car

Type 3 - WR parlour 2nd car

Type 4 - LMR kitchen car

Type 5 - WR kitchen car

Type 6 - LMR/WR parlour 1st car

Interior

Air conditioning

Motor cars

Auxiliary power

Bogies & couplings

Brakes

Data

Sub contractors

Staff instructions

LMR services begin

LMR Publicity

LMR brochure

LMR handbills

Controversy

WR services begin

WR publicity

WR publicity brochure

WR publicity leaflet

LMR Operations

WR Operations

Liveries

Rundown & withdrawal

After service & preservation

Disposal

Maintenance Manuals

Miscellaneous

Acknowledgments & Further Reading

Images

No vehicles were preserved.