Class 122 Gloucester RC&W Single / 2-car DMUs

Description

Ordered by the BTC in mid-1956, they were built concurrently with the Cross-Country Class 119s, as part of the same order which totalled 110 cars.

They were effectively a Class 116 DMBS (which were the High Density sets then in production at Derby) with a cab at both ends.

Construction

Bodies were an all-welded construction, with top hat section vertical pillars and z-section rails. Limpet blue asbestos supplied by J.W. Roberts & Co Ltd was sprayed to the inside of the 16g. steel bodyside and roof panels. Beclawat full-drop windows were fitted to the cast aluminium doors made by Lightalloys Ltd. The saloon windows did not have ventilators, air extraction was through the roof by standard BR type roof vents. The ceiling panels were 1/8 in. thick Laconite. Floor panels were a composite construction of 1/16 in. aluminium, 1/4 in. asbestos and 3/4 in. plywood. These panels were secured by Cyc-Arc studs and recessed barrel nuts. The guards van floor was a bitumastic compound laid on a dovetail section floor sheet, with aluminium chequer dumping plates inside the doors.

The underframe was a welded section of double channel longitudinals and crossmembers, with rolled channel section solebars. Additional longitudinal channel members with gusset attachments provided reinforcement between the bolster positions. Rolled steel sections were supplied by the Ayrshire Dockyard Co. Ltd. Standard type drawgear and Oleo-Pneumatic light steel buffers were used. Some later received oval buffers. Bogies were the conventional swing link bolster DMU bogie with spring side control and side friction blocks. The English Steel Corporation Ltd and George Turton, Platts & Co Ltd supplied the springs, and Taylor Bros & Co Ltd supplied the wheels and axles. The axleboxes were the roller bearing type from British Timken Ltd. Smith-Stone speedometer and mileage recording equipment was fitted.

Power equipment was the standard set up supplied by British United Traction, with the "A" type engine being chosen — the AEC 220. Graviner automatic fire protection equipment was fitted, as was ATC. There were two 98 gallon fuel tanks, as well as a 35 gallon tank to supply the two S. Smith & Sons (England) Ltd combustion heaters where were mounted longitudinally on each side of the frame between engine and bogie. Batteries were British Railways lead acid A2 type, of 440 A-hr capacity and were charged through a germanium rectifier by a belt driven C.A.V. alternator.

Originally the two exhaust pipes joined together above the destination indicator forming a small box. This was altered in the mid 1960s to two separate pipes.

Brakes

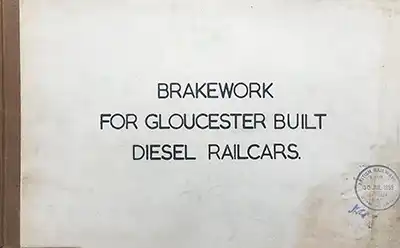

The standard Gresham & Craven quick release vacuum brake system was used, with 21 inch vacuum cylinders. All brake rigging was in aluminium alloy. Two Clayton Dewandre Co. Ltd. exhausters, belt driven from the gearbox input shaft, emptied the 15 cu.ft. of the vacuum reservoir. An emergency brake handle was fitted in the guards van, and there were hand operated parking brakes in each cab.

This BR booklet has diagrams showing the brakework equipment layout and lists all the components with part and drawing numbers.

Download PDF (14.8mb)

Interior

The cabs had flat top drivers desks. The cab roof and ceilings were fibreglass. Trico-Folberth screen wipers were fitted, and a hand-pump operated water spray unit. Access to the saloon/van was via a sliding door. On the end with the saloon behind the cab, folding blinds were fitted to the bulkhead windows. At the outer cab doors a tubular commode handle doubled as drain pipes for the roof gutters.

The saloon panels were Formica faced glossy bleached mahogany, with end partitions in Formica faced straight grained walnut. The non-smoking section (20 seats, in the saloon next to the van) was divided by a Formica faced blockboard partition, with full width glazing above seat level. The fawn linoleum was supplied by James Williamson & Son Ltd. Ceiling panels were an off-white eggshell semi-matt finish. Tubular anodised aluminium luggage racks were fitted above each window and on the compartment division. Ash trays were attached to the door side pillars where appropriate. Light fittings were supplied by J. Stone & Co (Deptford) Ltd.

Seats, in a 2+3 arrangement, were formed of base springs with foam rubber pads and squabs, covered in a "triangle" style patterned moquette, and fitted to Lace Web tubular seat frames. The facings were in blackberry Lionide with fawn piping. The guards van was painted fawn, and contained the usual first aid, fire fighting and emergency equipment.

| Length over buffers | 67' 1" | |

| Length of frame | 63' 6" | |

| Width over body panels | 9' 0" | |

| Height - rail to top of roof | 12' 4 1/2" | |

| Centre of bogies | 46' 6" | |

| Bogie wheelbase | 8' 6" | |

| Wheel diameter | 3' 0" | |

| Tare weight | 36 tons 6cwt | |

| Luggage capacity | 25 cwt |

Modifications

Later, Leyland 680 engines were fitted. The two-character headcode panels were plated over, and the exhaust pipes no longer joined at the top.

At some point (between 1981 and 1984) 55005 received Class 121 style exhausts.

DTS Through Access

The trailer vehicles were built with two solid partions dividing the passenger saloons into three unconnected saloons. On these bulheads the seating was six-across (two three seaters). At some point this was altered to provide through access to all saloons, probably to allow the vehicle to be evacuated in an emergency so all passengers could climb down to track level using the steps beside the cab. It involved reducing the seats at the bulkheads from six across to five across, an overall reduction of four seats (95 to 91). The diagram shows that one of the bulkheads had an open doorway, the second had a swing door.

The date of the change is unclear, but it was done before the end of 1973.

DTS Gangways?

One mystery is whether any of the DTS vehicles were gangwayed. The only suggestion that one or more were is a diagram showing the gangway added with the seating reduced to 89 — although it only shows it on the plan view, and the title specifically states "non gangwayed"!. There is no photographic evidence to support the conversion happened, and all the stock books that I have note them as non-gangwayed and either 95 or 91 seats.

If anyone has further information please get in touch.

Asbestos Removal

The vehicles were built with blue asbestos insulation in the cabs and saloon walls and ceiling. The page below is from a vehicle log kept by the RTC at Derby dated circa 1984 which included the asbestos status for each vehicle.

The codes for the asbestos columns are: / not built with blue asbestos; B - blue asbestos; and C - removed. In the remarks column OV means open van (no cage), while the VB 1988 records the six vehicles stripped by Vic Berry at Leicester in 1988: 55000/3/5/6/9/12.

Summary

Description

Works Photos

Diagrams & Design Codes

Numbering & Driving Inst.

Liveries

Data Panels

Operations

Disposal

Non-Passenger Use

Images

Details about preserved Class 122s can be found here.

Thanks to Chris Foren and Alan Rintoul for additional information.