Gearboxes

R14 Gearbox

The Self-Changing Gears (SCG) R14 was the most common type in use in DMUs, being fitted to almost all the 150hp engined vehicles.

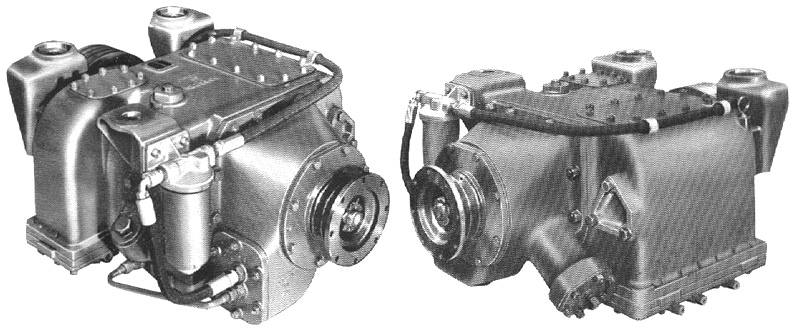

From the sectioned view of this gearbox the assembly the assembly of the various components may be followed and, and looking along the main shaft from the left to right, the direct-drive top speed clutch with its multi plate assembly is in the centre followed by the third, second and first speeds. Below this running gear can be seen the brake cylinder block containing three air cylinders and pistons operating brake bands for the three indirect speeds.

The pistons are of varying size according to the load transmitted which varies for each gear. Vee-belt pulleys are provided on the input and output couplings and these are used to drive an exhauster and generator.

A sectioned view of the top speed clutch operation piston, cylinder and linkage is shown on the lower left of the diagram. The multi plate clutch operates so as to lock together the running gear elements and by preventing rotation of the gear trains relative to each other, causes all the gearing to rotate as one unit thus providing a direct drive from the input shaft to the output shaft. It will be seen that air is admitted to the top speed operating cylinder forcing the piston upward and with it the piston rod, which in turn is linked to a lever pivoted on a pin. This lever, acting on a trunnion ring, converts movement of the piston into movement parallel to the input shaft and this applies the clutch.

Admission of air at main reservoir pressure to each of the gearbox cylinders is by the medium of EP valves operated by the gear change controller in the driving compartment.

The gearbox is lubricated internally by a gear type oil pump mounted on the front casing and oil, delivered under pressure through an external feed pipe, passes to an oil 'muff' fitted on the output shaft from whence it is delivered to the gear trains and bearings. A lubricating oil filter of the paper-element type is also provided.

The combination of a self-change gearbox and fluid coupling provides a highly effective means of transmission and the operation of a number of gearboxes from one control is simple. The driver moves his gear controller to the desired position and thus energises the appropriate EP valve which will allow air to operate the piston for a particular gear, this piston then applies the brake band and the required gear is engaged.

Gear Ratios

The gear ratios for the Self Changing Gears Ltd R14 gearboxes are:

1st gear 4.28:1

2nd gear 2.43:1

3rd gear 1.59:1

4th gear 1.1:1

R14 Front Mounting Brackets

The SCG catalogue lists many R14 variants, mainly due to different input / output pulley arrangements.

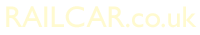

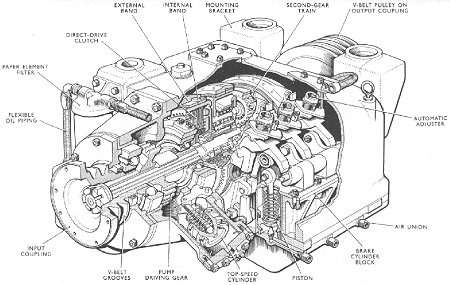

Another important difference was a different front mount used for different vehicles, seen in the first image.

There were two variations, seen here side by side:

The part number is cast on the side where they are fixed to the vehicle:

We'll identify the bigger left casting as "a", it is numbered 36475, and the smaller right one as "b", numbered 36127. When swapping gearboxes, it was a straightforward swap of the two brackets if they differed. The SCG catalogue denotes the following brackets were used on the following vehicles:

| 100 | a | 105 | a | 117 | b | 121 | a | |||

| 101 | a | 107 | b | 118 | b | 122 | b | |||

| 103 | b | 109 | a | 119 | b | 126 | a | |||

| 104 | a | 116 | b | 120 | a | 129 | b |

108s principally had the "a" type, other than 51416-24, 51901-50 & 52037-65, which had the "b" type. This seems to correspond with the movement of the coolant filler from the bodyside to the solebar.

Manuals

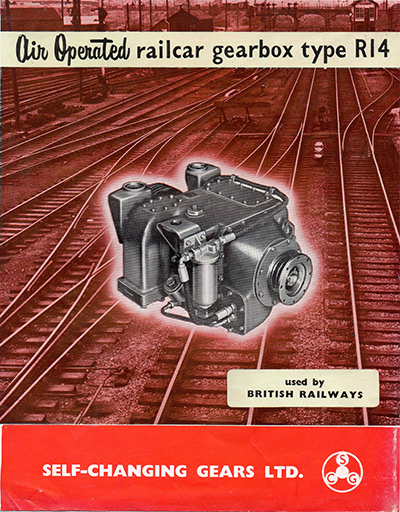

R14 Brochure

A promotional brochure dated 1955.

PDF (3mb)

R14 Service Manual

All the details for servicing. This same manual was used as the gearbox section in the BUT service manual.

PDF (10mb)

R14 Assembly

This folder contained several A4 sized photographs showing the assembly process in a step-by-step manner.

PDF (2.4mb)