DMU Engines

Leyland 680 150hp Engine

Introduction

BUT supplied two types of 150hp engines, the 'A' type (AEC 220) and the 'L' type, which was a Leyland 680.

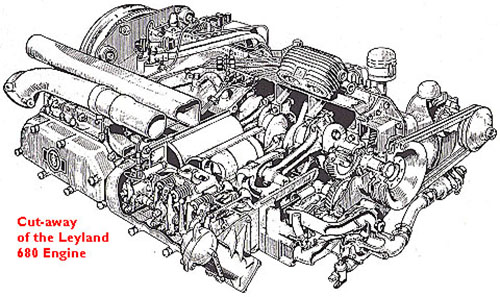

This was a horizontal six-cylinder 11.1 litre diesel engine with direct-injection, overhead-valve, four-stroke unit with a pump-driven water circulation system. Valves, rocker gear and injectors are carried in the two detachable cylinder heads, each head covering three cylinders. The valves are push-rod operated from the tappets and camshaft through rocker levers.

The crankcase and cylinder block form a monobloc casting, the cylinder bores being fitted with renewable liners. The gear-driven crankshaft is also housed within the crankcase.

The crankshaft is carried in seven thin-shell indium coated copper-lead bearings and carries a vibration damper at the front end.

The pistons are fitted with three compression rings, the top ring being chronium plated, and two scraper rings. The combustion chamber in the piston crown is of torodial form. The fully-floating gudgeon pins are retained by circlips.

The timing gears consist of a train of helical gears which drive the camshaft, fuel injection pump, water pump, compressor and engine tachometer generator through two idler gears driven by the camshaft gear.

Lubricating oil is pressure fed by a gear-type pump to the bearings etc., through drilled oilways. A by-pass centrifugal oil filter is incorporated in the system.

The fuel injection pump is mounted on the inner sump face and incorporates an idling and maximum speed governor and a diaphragm type lift pump. Multi-hole fuel injectors are fitted.

On later engines all electrical leads are carried in conduit and connected to a Niphan plug-and-socket, enabling the engine to be removed and replaced without disconnecting the terminal connections from the various components.

An oil-bath type air cleaner is mounted on the car underframe and is connected by hose to the inlet manifold.

A water-cooled oil cooler is mounted on the engine.

| Rating | 150 hp |

| Operating Speed | Max 1800 rpm |

| Min 375 / 400 rpm | |

| Cylinder Formation | Horizontal inline |

| Number of cylinders | 6 |

| Bore | 127 mm - 5" |

| Stroke | 146.05 mm - 5 3/4" |

| Compression Ration | 15.75:1 |

| Aspiration | Normal |

| Firing Order | 1.5.3.6.2.4 |

| Engine Rotation | Anti-clockwise Flywheel End |

| Camshaft Rotation | Anti-clockwise Flywheel End |

| Fuel Pump | Multi-element CAV |

| Injectors | Leyland or CAV |

| Governor | CAV |

| Pump Timing | 30 degrees BTDC |

| Injector Pressure | 140 / 145 Atmos. or 2060 / 2135 psi |

| Max Governed Speed | 1900 / 2000 rpm |

| Oil Capacity | 5.5 gallons |

| Operating Oil Pressure | 55 / 60 psi |

Variants

The 680 was a popular Leyland engine also used extensively in road vehicles in both horizontal and vertical forms. As the engine developed over the years, some variants found their way onto DMUs. The differences are listed below. Later the turbocharged variation, the TL11, was also used. The table is from a BR document dated 9/89.

| Engine: | 680/1 | 680/13 | 680/1595/0 | 680/1595/1 | 680/4041 |

|---|---|---|---|---|---|

| Easily identifiable by: | Bent fuel pipe mounting bracket. Originally air cooled compressor | As 680/1 with long leg mounting bracket with throttle motor mounted on bracket | Straight fuel pipe brackets, water cooled compressor, CAV NN pump which is oil pressure lubricated | As 1595/0 but with Friedmann & Maier pump | Non-turbo TL11? |

| Leyland Part No: | 545817 | 318703 | RE 680/1595 | RE 680/1595/1 | RE 680/4041 |

| BR Cat No: | 15/29975 | 15/85397 | 15/1137 | 15/1631 | 15/1717 |

| Fuel Pump: | CAV 'N' | CAV 'N' | CAV 'NN' | Freidmann & Maier | Freidmann & Maier |

| Timing (BTDC): | 30° | 30° | 30° | 22° | 22° |

| Injector Release Pressure: | 165-170 ats. | 165-170 ats. | 230-235 ats. | 230-235 ats. | 175-180 ats. |

| Injector Body CAV Part No: | BKB 75S 5006 | BKB 75S 5006 | BKBL 97S 5426 | BKBL 97S 5426 | BKBL 97S 5006 |

| Injector Despatch No: | 5246605 | 5246605 | Special to BR | Special to BR | 5246601 |

| Nozzle Despatch No: | 5620916 | 5620916 | 5621812 | 5621812 | 5621057 |

| Nozzle Type No: | BDLL 140S 6205 A | BDLL 140S 6205 A | BDLL 140SY 6768 | BDLL 140SY 6768 | BDLL 140 SY 6306 |