Vacuum Brakes

Exhauster

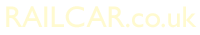

The rotary exhauster is belt driven from the input end of each gearbox and is a vane type pump consisting of a body fixed to the vehicle underframe which has inside it a rotary mounted eccentrically within the bore of the body casting. The rotor has a number of radial slots cut in it and vanes or blades slide in these slots. The eccentric positioning of the rotor and the length of the blades are arranged so that the tips of the blades can at all times contact the inner surface of the bore. To ensure that the blades do maintain this contact when the motor is stationary, or only slowly rotating, a cam ring concentric with the bore is provided upon which the inner edges of the blades ride. The action can be seen by following the motion of the blade which is at 6 o'clock position in the drawing. As the motor commences to revolve the cam ring will maintain the blade in contact with the bore but it will be noticed that the outer surface of the rotor will be moving about its own centre and away from the bore. The following blade will perform an exactly similar cycle as it is rotated. The space between these two blades will thus be seen to increase to a maximum at the 12 o'clock position and then decrease as the space again approaches the 6 o'clock position.

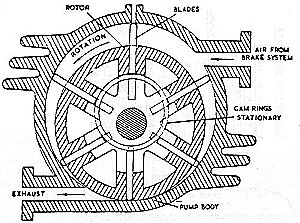

The pump is provided with an inlet port where the space is decreasing as shown. The inlet port connects with the vacuum reservoir and as the rotor revolves air is drawn into the pump body. As the following blade passes the inlet port the air is trapped and will be subject to some compression before the leading blade uncovers the exhaust port. To provide air seals between the blades and the body oil is supplied into the interior and some of this oil will be carried over with the exhaust air into an oil separator where it is recovered and the re-circulated. The exhauster is efficient at idling speeds and can thus restore vacuum conditions when a vehicle is at rest after a brake application has been made. When the pump is running at speed, centrifugal force will ensure that the radial blades bear firmly against the inner surface of the bore and the cam rings will thus be necessary only at low engine speeds.

For the efficient operation of the exhauster it is necessary for sufficient oil to be supplied to the exhauster bearings and also into the body of the exhauster to provide an effective seal between the blades and the bore of the body. The air exhausted, therefore, contains a considerable proportion of oil and it is necessary to force this through an oil separator unit before allowing it to escape to atmosphere.

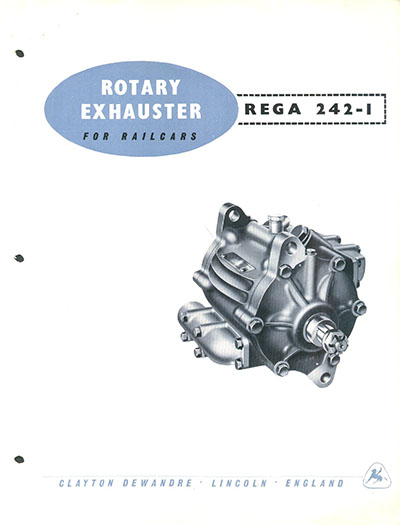

Clayton Dewandre REGA 242

Most (all?) railcars were fitted with Clayton Dewandre REGA 242 exhausters. The manufacturers literature (dated October 1955, 2.1Mb PDF) deals with its operation in more detail as well as servicing and overhaul. There are two versions of page 2 in the pdf, one is from a later version with alternate diagrams.

The front roller bearing on this exhauster is a RHP LRJ 7/8 and available from most bearing stockists. The other end which is a ball bearing is NTN RLS7. The seal is available from Barnwells of Birmingham (0121 429 8011), their part no is :- SD19311862 NBR04 (information - Chris Bull).

Vacuum Brakes

General Description

Operation

Exhauster

Feed Valve

Isolating Valve

Brake Cylinder

Direct Admission Valve

Driver's Brake Valve

Maintenance:

Adjusting Brakework

Feed Valve Overhaul

Isolating Valve Overhaul