Class 108 Derby 2,3 & 4-car DMUs

Description

Vehicle bodies and underframes were of aluminium construction (an Al-Mg-Si alloy), except for the headstocks and certain diagonal members behind the buffers. The 79xxx Derby Lightweights had used the ICI 'Kynal' allow, the 108s used the equivalent specification material from other suppliers. Driving cabs, inner ends and buffer beams were of mild steel and cab roof domes were fibre glass mouldings. The high proportion of aluminium gave a weight saving compared to similar units and hence an improvement in power to weight ratio. Small round buffers of the Oleo type were fitted, but later the large round buffers of the type used on the 64ft underframe vehicles could be seen on some cars.

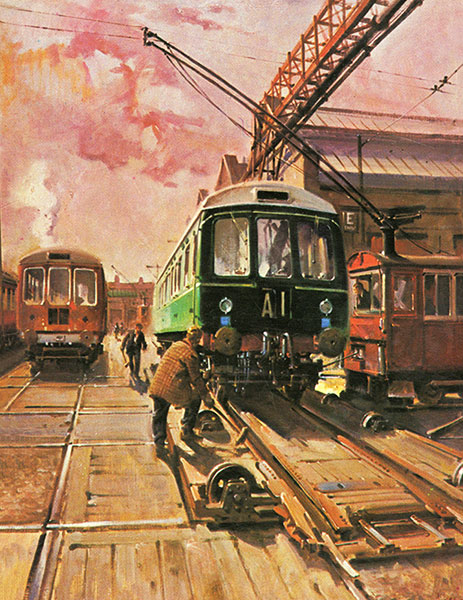

The Terence Cuneo painting shows a 1958 scene at Derby Works with a completed vehicle on the traverser and another in undercoat on the left. This featured on the cover of a 1974 promotional brochure "A Century of Progress" celebrating 100 years of Derby Works.

The DMBS and the DMC vehicles were powered by two underframe mounted Leyland 150hp engines, driving a fluid flywheel, freewheel and 4-speed epicyclic gearbox to a final drive mounted on the inner axle of each bogie. Bogies were of the single bolster DD7 type for the power cars and of the DT8 type for trailers.

Originally the earlier driving cars were equipped with two character train describers under the central driving cab window flanked by two white marker lights. Destinations were displayed in a small box in the cab roof dome above the central window. For cars built 1960 onward the cab design was modified to accommodate a four character headcode box in the cab roof dome, the destination display then being relocated to the top of the central cab window. The last set constructed to the original pattern was M50935/M51572 and the first set to the new design was M51416/M56271. All sets delivered to the ER had brake pipes mounted on the buffer beam (as normal DMUs), those delivered to the LMR, except for the first five sets, had brake pipes mounted below the buffer beam.

50601/56192 was the first of the class to undergo refurbishment in 1975, this was the first production set to be tackled after the trial Class 101.

Latterly, the entire remaining fleet was converted to the water coolant saloon heating system at Carlisle Currock C&W repair shops.

With so many vehicles there were a lot of internal styles when new. This is a TSL vehicle.

Summary

Orders

Description

Works Photographs

Modifications

Refurbishment

Diagrams

Numbering & Driving Inst.

Liveries

Operations

- Scotland

Accidents

Decline

Non-Passenger Use

Images

Details about preserved Class 108s can be found here.